Sustainable concrete: a stronger and more durable construction material developed from recycled clothing

Australian engineers are revolutionizing concrete: using recycled textile fibers not only makes the building material more durable, but also helps reduce waste – a major breakthrough for the construction industry!

In an innovative move to promote sustainable construction practices, Australian engineers have developed a way to use waste textiles , such as old carpets and clothing fibers , to improve the crack resistance and strength of concrete.

This technique could not only extend the life of concrete structures, but would also provide an environmentally friendly solution to reduce textile waste.

The research team is working closely with partners such as Textile Recyclers Australia and Godfrey Hirst Australia, as well as local authorities in Victoria, to investigate the effectiveness of this technique in field studies.

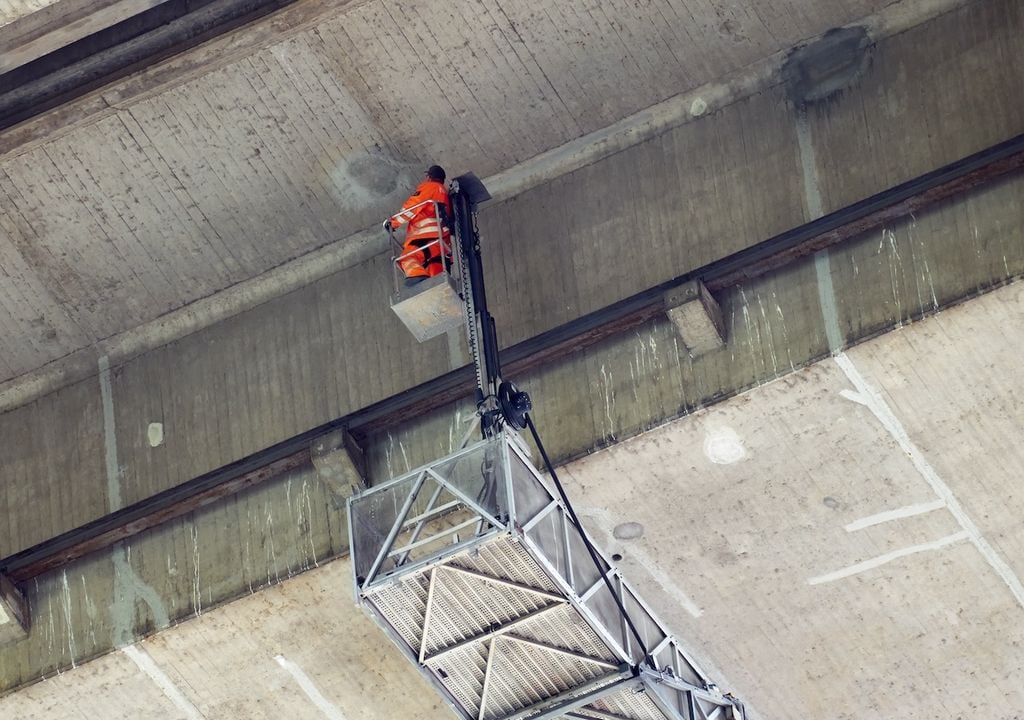

Dr Chamila Gunasekara from RMIT University is leading the research project, which aims to reduce early-stage shrinkage cracking in concrete by up to 30%. This approach could extend the life of structures and save significant costs in the long term.

In Australia, the annual cost of repairing cracked reinforced concrete is around A$8 billion.

In the United States, the cost is approximately $76 billion a year.

The team's latest research results were published in the journal Construction and Building Materials and show that textile waste can not only improve the mechanical properties of concrete, but also reduce its impact on the environment

Engineers in #Australia have developed a method to enhance concrete strength and reduce cracking by up to 30% using scrap #carpet fibers, promoting sustainability in construction. @rmit https://t.co/1Am3BWLAki https://t.co/dXOsVtlWdO

— TechXplore (@TechXplore_com) November 11, 2024

Crack prevention: a long-standing problem in construction

"Our research shows that carpet waste can increase the tensile strength of concrete by up to 40% and significantly reduce the risk of cracking by reducing shrinkage."

"Our research shows that carpet waste can increase the tensile strength of concrete by up to 40% and significantly reduce the risk of cracking by reducing shrinkage."

Recycling waste as a solution to environmental problems

The use of carpet and textile waste in concrete construction offers a solution to the global waste problem.

"Australia is the world's second largest consumer of textiles per capita and huge amounts of textiles are sent to landfill every year," Gunasekara explains.

Dr Shadi Houshyar, a textiles and materials scientist at RMIT, highlights the challenge of recycling specialized textiles, such as firefighter clothing, which are difficult to recycle due to their specific properties.

“Around 70% of textile waste could be converted into useful fibers, providing a sustainable source of materials for the construction industry,” Houshyar said.

This innovation by engineers at RMIT University uses discarded clothes and other textiles to make a popular building material crack-resistant and stronger. ️️

— RMIT University (@RMIT) November 12, 2024

Learn More: https://t.co/YkN3E2YZiK pic.twitter.com/JuuLoY8LrZ

Field trials and international cooperation.

The research project is supported by the ARC Research Centre for Industrial Transformation and includes laboratory tests and field studies in collaboration with Luleå University of Technology in Sweden. The aim is to test the suitability of the materials for real construction projects and to model the behavior of fiber-reinforced concrete in different environments.

The results of the study and accompanying publications, including a data-enhanced approach for the analysis of early-age drying-induced moisture transport in cast-in-place textile fiber-reinforced concrete (published in the Journal of Building Engineering) and the reuse of blended fabric waste for sustainable cement -based composites (published in Construction and Building Materials), show the great potential of this approach.

Research results and challenges

Carpet fibers contribute to increasing the flexural and fracture strength of concrete and can positively influence shrinkage behavior . A fiber content of 0.3% showed the best results by refining the pore structure and increasing the proportion of closed pores. This reduces the risk of drying shrinkage and improves the structural integrity of the concrete.

However, increasing the fiber content to 0.5% resulted in a slight reduction in compressive strength and an increase in porosity. This suggests that a precise dosage of fiber is required to achieve optimal results.

Future research approaches

Researchers recommend further study of fiber distribution to achieve more uniform structure and strength.

In addition, a long-term study would be required to assess the durability of reinforced concrete mixtures in large-scale applications. Innovative processing methods and predictive models could further improve the efficiency and cost-effectiveness of using textile fibers in the construction industry.

This research not only shows the potential of textile waste to strengthen concrete, but also the possibility of establishing an environmentally friendly alternative for the construction industry: a solution that increases the lifespan of concrete structures while reducing waste generation.