Recycling revolution: Crisp packets that perform like plastic but recycle like paper

A novel polymer that performs like plastic but recycles like paper offers an environmentally friendly alternative to non-recyclable plastic crisp packets.

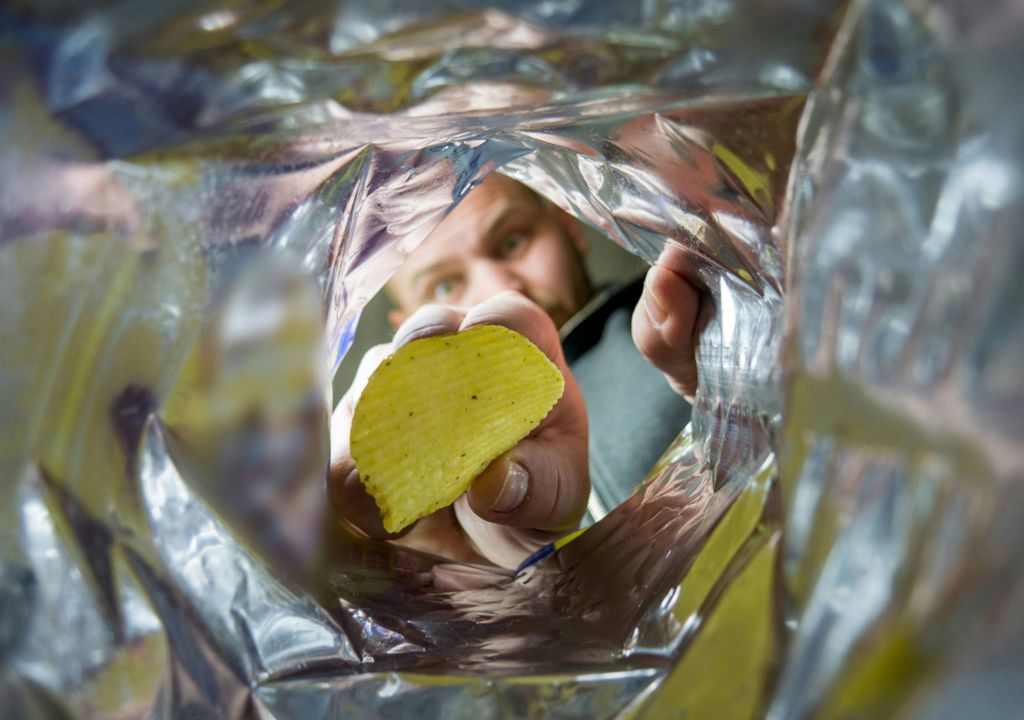

Over eight billion crisp packets are thrown away in the UK each year; these little plastic bags are either incinerated, or end up in landfill where they can take up to 80 years to decompose.

To combat to growing problem of crips packet pollution, the first fully recyclable paper crisp packets have been launched, providing an environmentally friendly alternative which can be recycled along with other paper recyclable items with normal kerbside collections.

Dissolvable polymer

“Brits consume over eight billion packets of crisps each year, the majority of which are not recyclable and end up in landfill or incinerators – that’s a lot of waste and a huge environmental problem,” says Tom Lock, CEO of British Snack Company. “In partnership with Evopak and using exciting new polymer technology, we have created the first fully recyclable crisp packet – something that consumers have been demanding for a long time.”

“We are delighted to be the world’s first crisp brand to bring to market a fully recyclable paper pack,” he adds. “In addition, we make our crisps on a UK farm that not only grows its own potatoes but is powered by renewable energy! So we like to say that our crisps don’t just taste good, they do good too.”

The novel packaging uses an innovative high-performance polymer called Hydropol, instead of conventional plastic and is similar to the base plastic already used for dishwasher tablets, ingestible pill casings and soluble stitches.

The non-toxic and marine safe polymer can be extrusion coated and laminated onto paper to impart strength and barrier properties against oxygen, oil, and grease while a very thin layer of vacuum deposited aluminium helps maintain freshness without affecting recyclability.

The polymer can be recycled, re-pulped, composted, and is compatible with anaerobic digestion where it can be turned into clean energy. And if accidentally released into the natural environment, it dissolves and biodegrades rather than breaking down into harmful microplastics, so has a safe end-of-life even if poorly disposed of.

The packets are certified as recyclable and carry the green recycle logo, meaning they can be recycled in consumer kerbside collections along with other paper material, unlike other crisp packets.

On the market

The polymer is already used in product and packaging design, in a wide range of industries from fashion, hospitality, healthcare, food packaging, logistics packaging, industrial, nonwovens, and other packaging such as reusable, heat sealable paper mailing bags, dry pet food sacks, and window patch boxes.

Daniel McAlister, Director of Business Operations at Evopak, says: “We have developed a unique paper which has the potential to revolutionise packaging as we know it, thanks to the unique properties of Hydropol. The paper can be used in a range of applications from snacks and confectionary, to petcare and dry foods and cereals, and costs the same as existing materials.”

Other applications under development include injection moulded parts such as golf tees, nonwoven fibre for applications such as flushable wet wipes and cellulose combinations for thermoformed trays.