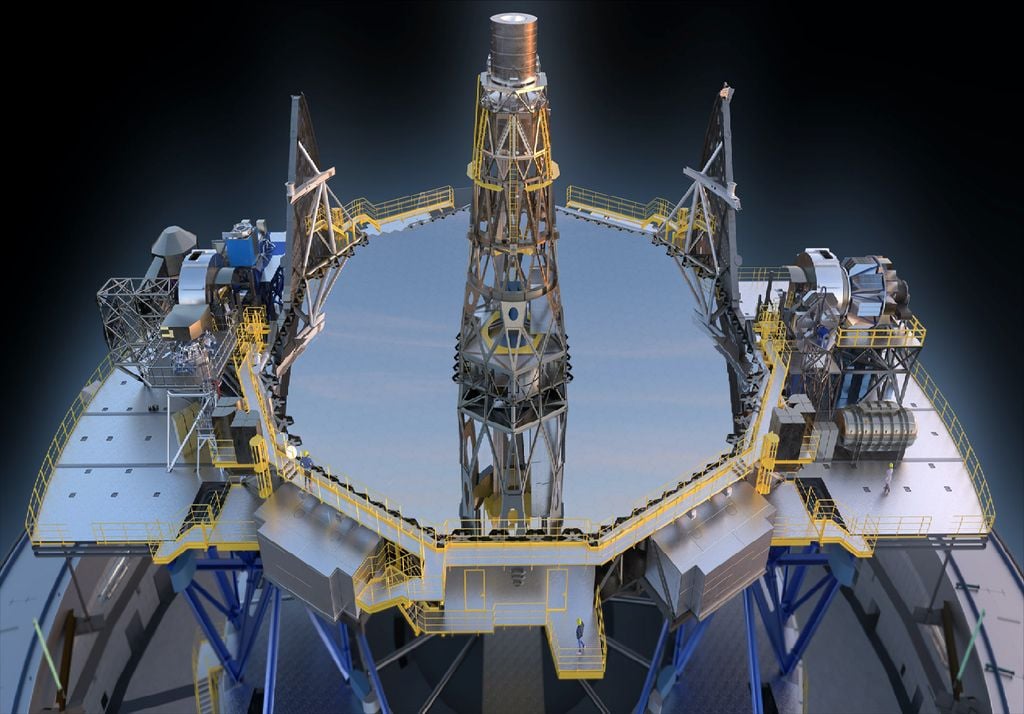

The last cell of the largest hive ever built has been completed: It is the 39 metre mirror of the ELT telescope

Inspired by the hexagonal cells of beehives, the mirrors of the largest telescopes are made by assembling numerous small hexagonal mirrors to form a large reflecting "hive". This is what was done with the Extremely Large Telescope. Let's understand the reason for this technique.

The ELT telescope , Extremely Large Telescope, will be the largest ever built . Its primary mirror will have a diameter of 39 metres and will be housed in a circular-based dome with a diameter of 90 meters and a height of 80 metres.

The place where the construction is underway is the Cerro Armazones at an altitude of 3600 metres in the Chilean Atacama Desert.

How is it possible to make such a large mirror

The primary purpose of a telescope is to collect much more light from any astronomical object than it can collect the pupil of the eye . The light collector can be a lens , usually glass, or a mirror .

In the case of the lens, the light from the astronomical object that affects the lens is conveyed to a point in the focal plane, where the image of the object is formed, thanks to the phenomenon of refraction.

In the case of the mirror, the incident light on the mirror is conveyed to the focal plane thanks to the phenomenon of reflection.

The larger the lens or mirror, the greater the amount of light you can collect. Collecting a larger amount of light has two advantages, it allows you to observe weaker objects, but it also allows you to decrease the exposure times (if I double the area of the mirror I get the image of the same object in half the time) , a circumstance that has numerous advantages for astronomers.

The need (but also the desire) to observe objects that are increasingly distant and weak explains why increasingly larger lenses and mirrors have been built.

Thermal inertia, the enemy of the great telescopes

However, the realisation of large lenses has an obstacle in thermal inertia. When between day and night, but especially between summer and winter, the average air temperature changes , the glass monoblock of which the lens is made up expands or contracts . The greater the mass of glass, the longer the process of expansion (if the temperature increases) or contraction (if the temperature decreases).

By continuously changing the temperature of a convergent glass lens, it also changes the focal distance . If the instrument that photographs the object is fixed and perfectly positioned on the focus on a given day, as the hours pass by changing the temperature of the lens, it changes its focal length and the image of the astronomical object will be blurred.

The most advantageous technique today in the realisation of large diameter mirrors is to build them as an assembly of several segments, generally hexagonal in shape, just like cells of a large hive . Being small they have a small thermal inertia.

Each hexagonal mirror having reduced size and thickness has low thermal inertia . By assembling more and more of these hexagonal segments you can build an ever larger mirror.

The large beehive mirror of ELT

Today the record in the total number of segments is held by the ELT Telescope, Extremely Large Telescope, with 798 hexagonal segments.

Each segment, that is, each hexagonal mirror with a thickness of 5 cm, is made up of a material called ZERODUR , a glass-ceramic with low thermal expansion, made by the German company SHOTT , the official supplier of the 949 segments.

Each segment (as shown in the figure above), once completed, is transported to France at the Safran Reosc company. From these it is cut into a hexagon shape and its surface is sanded to an accuracy of 10 nanometres. This means that residual surface irregularities do not exceed 10 millionths of a millimetre.

Once ready, each hexagonal segment is transported by ship to Chile where it will reach its final location . A few kilometres from Cerro Armazones, where the telescope dome is being finalised, each segment is coated with a layer of silver so as to become reflective, and thus become a mirror.

The 798 hexagonal mirrors will soon be assembled to form a single 39-metre-diameter mirror . This assembly operation will require the skills of other specialised companies. In fact, the mirrors will be connected to 2500 mechanical actuators. Their task is to ensure that the mirrors are perfectly aligned between them, within 2500 nanometres, so as to constitute a single smooth surface without discontinuity between a segment and the adjacent one.